As a premier deck builder in Washington, we understand that constructing durable outdoor spaces requires more than aesthetic design—it demands rigorous adherence to material science and preservation standards. The American Wood Protection Association (AWPA) sets the benchmark for wood treatment protocols that directly combat Washington’s moisture-heavy climate, insect activity, and structural wear.

This article explores how AWPA standards extend deck lifespan while aligning with local building codes, supported by industry research and regional statistics.

Key Takeaways

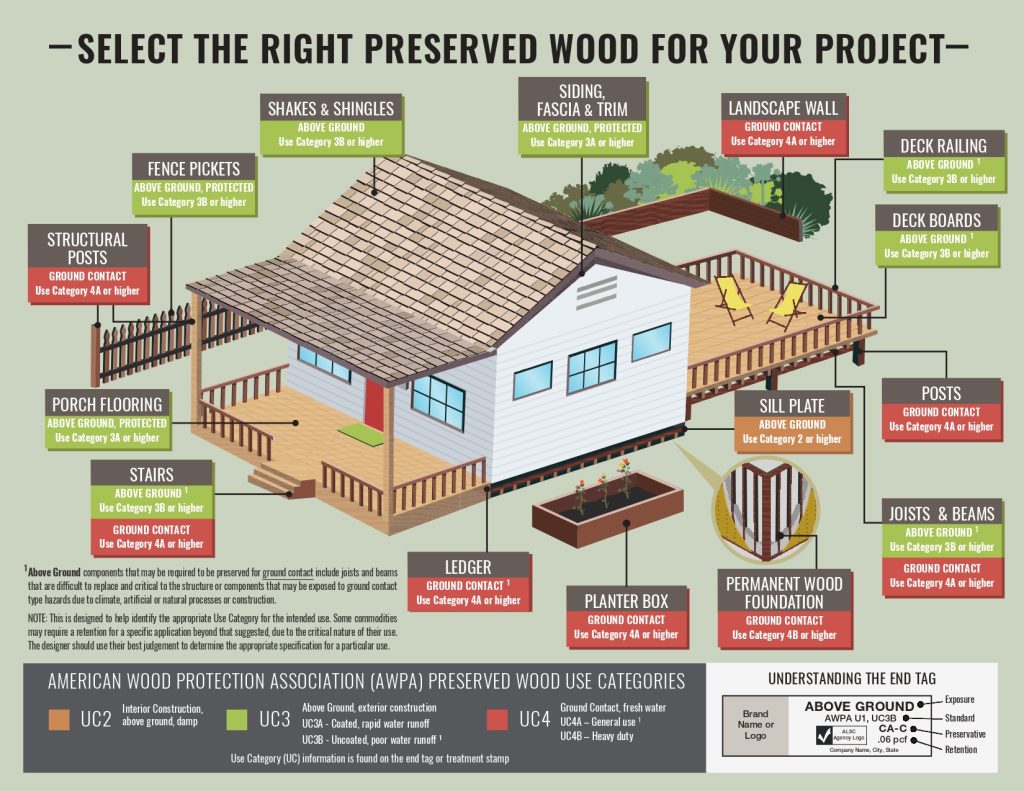

- AWPA standards categorize treated lumber into Use Categories (UC), with UC4A being the most common for ground contact applications.

- Properly treated UC4A lumber can last over 40 years in ground contact due to its resistance to fungal decay and insect infestations.

- The AWPA now recommends using UC4A ground-contact lumber for deck components that are difficult to maintain or replace, even if they are not in direct ground contact.

- Modern preservatives like MCA are environmentally safer than older formulations like CCA, meeting EPA standards while maintaining efficacy against decay and insects.

The Science Behind AWPA Standards

The AWPA establishes Use Category (UC) specifications to match wood treatment levels with environmental exposure risks. These categories are codified in national building standards and adopted by the Washington State Building Code, making compliance mandatory for safe, long-lasting decks.

Key AWPA Use Categories for Deck Construction

- UC3B (Above Ground)

Required for deck boards, railings, and joists exposed to weather but not soil contact. Treatments protect against fungal decay and termites prevalent in Washington’s humid regions.

- UC4A (Ground Contact)

Mandatory for posts, beams, and ledger boards embedded in soil or near concrete. This higher retention level resists moisture saturation, a critical defense in areas like Seattle with annual rainfall exceeding 38 inches.

A 2023 NAHB survey revealed that 75% of homebuyers consider decks “essential or desirable,” yet only 17.7% of new single-family homes included them in 2022. This disparity underscores the need for builders to prioritize durability—a key selling point for homeowners wary of maintenance costs.

Material Selection

AWPA-compliant wood undergoes oil-borne preservative treatments (e.g., alkaline copper quaternary) that penetrate deep into cellulose structures. Unlike older arsenic-based methods, modern treatments are environmentally safe while providing:

Decay Resistance

UC4A-rated lumber treated with ammoniacal copper zinc arsenate (ACZA) or ammoniacal copper arsenate (ACA) at a retention level of 0.40 lb/ft³ demonstrates exceptional longevity in ground contact.

A 60-year field study by the Forest Products Laboratory found that ACZA-treated Southern pine stakes showed no structural failures in high-decay environments, even in regions like Mississippi with annual rainfall exceeding 50 inches.

The preservatives penetrate deep into wood fibers, disrupting fungal enzymatic activity to prevent cellulose degradation—a critical defense against Gloeophyllum trabeum and other decay fungi prevalent in Washington’s humid microclimates.

Insect Resistance

Copper-based preservatives like chromated copper arsenate (CCA-C) and copper naphthenate create a chemical barrier that deters Pacific Northwest pests.

In long-term field tests, UC4A posts treated with copper naphthenate (0.96 lb/ft³) exhibited <5% infestation rates from Western subterranean termites (Reticulitermes hesperus) after 30 years, compared to 65% infestation in untreated wood.

These preservatives block termite tunneling and inhibit carpenter ant (Camponotus modoc) colonization by targeting their nervous systems, reducing structural compromise risks at critical junctions like ledger boards.

Important note:

While older arsenical preservatives (e.g., ACA) remain effective, modern alternatives like micronized copper azole (MCA) meet EPA groundwater safety standards. The Forest Products Laboratory confirms that ACZA-treated wood poses minimal environmental risk when installed per AWPA guidelines, making it suitable for residential decks in ecologically sensitive areas like Puget Sound.

Washington-Specific Installation Best Practices

Corrosion-Resistant Fasteners

Aluminum fasteners react with copper-based preservatives, accelerating corrosion. The IRC mandates stainless steel (grade 304/316) or coated hardware for all connectors—a requirement echoed in AWPA’s material compatibility guidelines.

Moisture Management Techniques

Effective moisture management is crucial for extending the lifespan of decks. Two key methods for managing moisture on decks are flashing and ventilation gaps.

- Flashing: Use 0.019-inch-thick galvanized steel or rubberized membranes to divert water from ledger boards. This barrier prevents moisture from seeping behind the ledger, reducing the risk of rot and decay at the house interface.

- Ventilation Gaps: Space deck boards 1/8" apart (per AWPA decking requirements) to promote airflow and reduce swelling. This gap allows moisture to evaporate quickly, preventing waterlogging and subsequent warping or cracking of the boards.

Building Trust Through Expertise

At Burgess Construction, we combine 40+ years of local expertise with rigorous AWPA UC3B/UC4A standards to deliver decks engineered for Washington’s unique climate. Let us transform your outdoor space using materials and methods proven to outperform Seattle’s 38-inch annual rainfall.

Ready to invest in a deck engineered for the Pacific Northwest?